VeloNews vibration transmission tests

I'm really enjoying the recent series of VeloNews bike test articles. First it was aero mass-start road bikes (April 2011 issue) and now it's "endurance" bikes (June 2011). This one is especially interesting because while there's already plenty of windtunnel data out there, vibraton data is less readily available. Wind tunnel tests are extremely trickly because the result depends so strongly on the size of the bike chosen, what's bolted on it, and the position of the rider. With vibration testing, we're getting closer to fundamental engineering, and I would hope the results would tend to be less dependent on assumptions.

VeloNews isn't the first to do such tests, of course. I've already commented on Champoux's work in which he analyzied the spectral distribution of vibrations transmitted to a bike frame using a treadmill with a bump attached.

Hastings did a study, also with a treadmill with a bump, at M.I.T. comparing old Cervelo frames: one aluminum, one carbon fiber, and the other steel. Each bike had the same geometry, the same components, and tires pumped to 7.6 bar. Forks also were apparently the same. Hasting's result was consistent with typical subjective evaluations: the Al frame had the highest peak acceleration (2.5 g) followed by the carbon fiber and steel in a virtual tie at 2.3 g. The range of acceleration (from negative to positive) showed a similar trend, with the Al at 3.0 g with the roughest ride, followed by the carbon fiber and steel at 2.7 g. The steel tested with slightly less vibration than the carbon fiber, but the difference was too small to claim statistical significance.

So the bike matters, apparently. So with this background, I was interested in seeing what VeloNews found testing four present-day carbon fiber frames.

One difference: the VeloNews test used Kreitler rollers instread of a treadmill. They welded steel rods onto the front 3-inch and the frontmost rear 4.5 inch rollers to produce bumps. with different periods (it's tempting to say the periods were in a 3:2 ratio but the bumps likely result in an offset from this nice rational result). They then mounted accelerometers to the top of the seatpost (eliminating the effect of the seat),the top of the steerer tube (eliminating the handlebar and stem), and to the front and rear dropouts. Results were combined from these accelerometer readings.

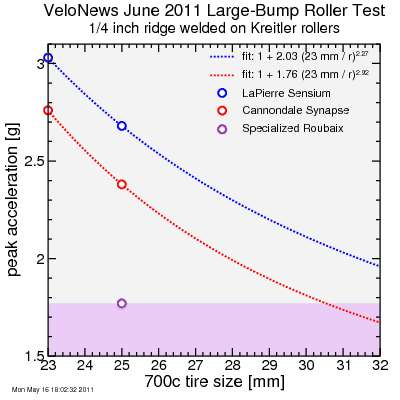

Numbers were in the same range of the Hastings results: up to 1.82 g peak acceration for the small-bump test, up to 3.03 g peak acceleration for the large bump test. I don't want to reveal all of the results here: you should buy the magazine or access it via their web site. But an aspect I found particularly interesting and one I hadn't seen measured before was the effect of tire size. They compared a 23 mm tire with a 25 mm tire for two of the test bikes: the LaPierre Sensium and the Cannondale Synapse.

If you compare a 23 mm to a 25 mm tire, the rolling radius of the 25 mm tire is slightly greater: for every turn of the wheel the bike moves slightly further. But there is a larger relative difference in the minor radius: the radius of the tire perpendicular to the rolling direction. When riding over rough roads, if I have wider tires, my tire drops less into holes narrower than the tire width than it does into wider holes. The wider the tire, the wider the hole needed for the tire to fall completely into the hole. So you'd expect a wider tire to provide a smoother ride on real-world bumpy roads. But the VeloNews test doesn't address this effect: the bumps are essentially infinitely wide.

Another advantage of a fatter tire is you can pump it to lower pressure without fear of road-rim impact. Additionally, at the same tire pressure a fatter tire of the same suppleness may have lower rolling resistance since the contact patch is less eccentric and requires less depression of the rubber at its center. So for both of these reasons you can run the fatter tire at lower pressure, reducing the bump transmission. But the VeloNews test doesn't address this either: they ran both a 23 mm tire and a 25 mm tire at 90 psi (6.2 bar). They reported tests at 120 psi (8.3 bar) exceeded their accelerometer range.

So you might not expect they would measure much of an effect from tire size, since two "obvious" advantages of fatter tires weren't exploited. Here's the result:

Despite only a few data points, I boldly extrapolated the results out to 32 mm tires using simple power-law models. I'm assuming an asymptote of 1 g: the accelerometers will measure the acceleration of gravity when at rest (consistent with the M.I.T. study). You can see that tire size has a large effect (the power law exponent is greater than two in each case), but not enough to close the gap between the Roubaix and the other two bikes.

However, with larger tires one typically uses lower pressure. So I assumed that one pumps the tires to a given contact patch length. The area of the contact patch would then be porportional to the width of the tire, and therefore, assuming contact patch size is proportional to pressure, the pressure is inversely proportional to the tire width (this is actually a fairly bad assumption, due to sidewall stiffness, but close enough to justify my pressure-width relationship). This is also consistent with a given force on the bead, since force on the beat is proportional to tire width multiplied by tire pressure. I then assume that acceleration from a bump is proportional to the square of the pressure. This seems plausible since lower pressure reduces bump transmission at least two ways. For one, it reduces the force which can be transmitted to the tire by a small bump of a given size. Second, it increases the contact patch of the tire (averaging the roughness over a larger section of road).

The result is then as shown in the second plot. From here it appears the Roubaix with 25 mm tires would have about the same large-hit acceleration as the Cannondale with 27 mm tires or the Bianchi with 29 mm tires. Note this isn't quite right, because the Roubaix was tested with the same pressure @ 25 mm as the other two were @ 23 mm, so the difference is even larger than this.

These results certainly suggest, even for the same frame material (carbon fiber), the design of the frame and fork can have a considerable influence on the comfort of a bike over rough roads, even comparable to relatively large differences in tire size.

Comments

I've been unable to find the original article online though :(

Perhaps you know where to find it?